Improvement to battery test stations

Any test done with the improved test stations will be marked with an asterix* in the comparator and the actual review of the cell will include temperature charts for the high current drains. I will add temperature curves for the 3 highest test currents, these charts will show temperature increase, not the full battery temperature that will be 25°C to 30°C higher.

4 terminal sense

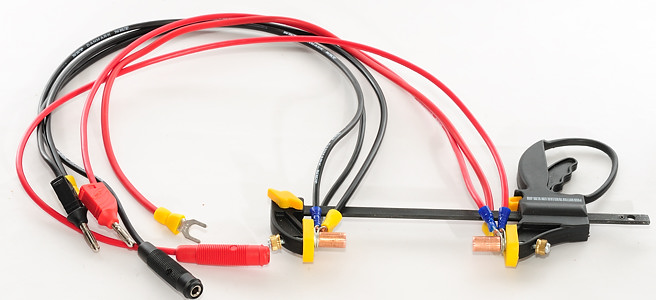

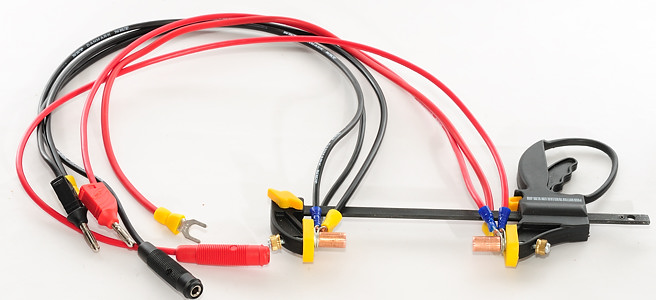

I have for a long time used a clamp for battery connections when testing, it has fairly low resistance and can handle a lot of current. But some connection resistance is still present in it and means the results at high current do not reflect the full battery performance.

Because the connection resistance will vary slightly each time I connect of a new battery, the curves might not match perfectly at high currents with the clamp.

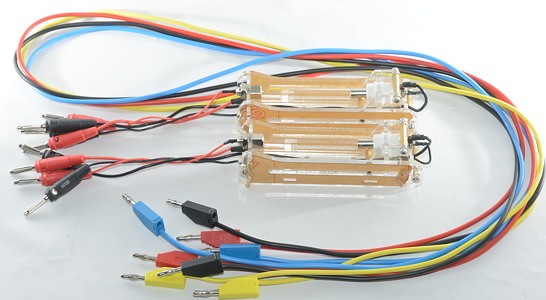

With the aviablity of ready made 4 terminals rigs, I decided to upgrade my two LiIon test stations.

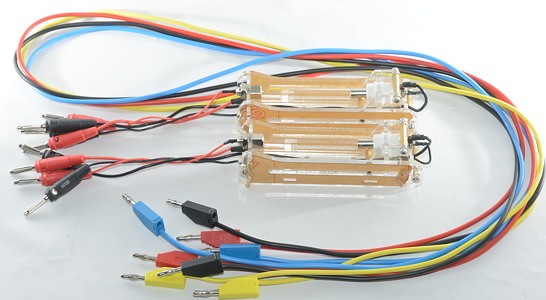

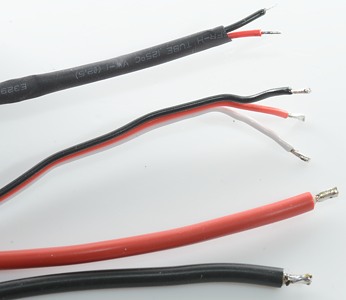

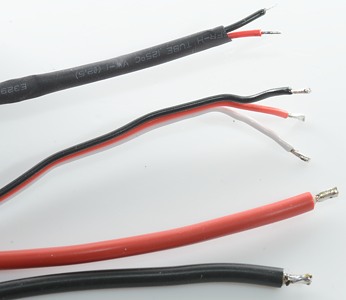

For that I needed two 4 terminal units and some better wires, the supplied wires are rather thin and short. For wires I bought ready made cables (I am lazy) in four different colors.

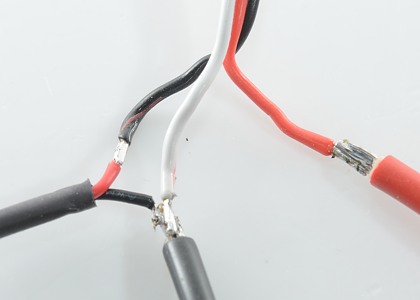

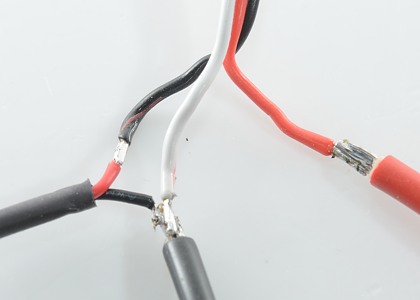

I removed the old wires and and cut new the wires at the midpoint.

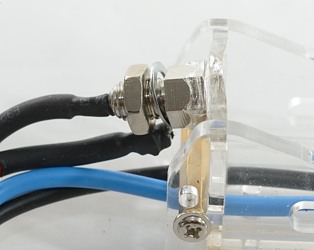

Wires mounted, the red/black for current, the yellow/blue for voltage sense.

With a battery in it. The rig can handle over 70mm long cells.

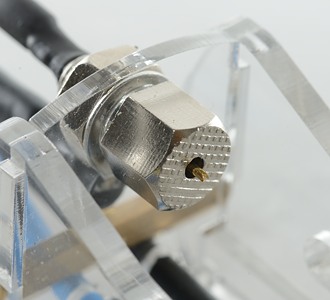

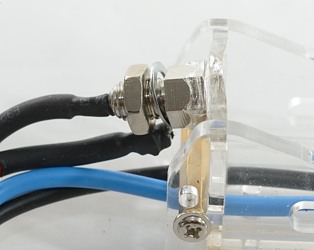

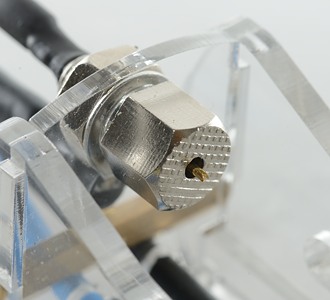

Here is a closeup of the each connection, the pin in the middle is used for voltage sense and do not have any electric connection to the metal surrounding it, that is used for the current.

Nothing last forever, this includes test rigs when batteries gets hot. In the future I will add a temperature cutout, i.e. the test will stop if the battery gets to hot.

High current test will show higher output voltage, because I am measuring directly on the battery terminals with this 4 terminal rig

Temperature

For temperature sensing I made a few more of the units I have been using for temperature when testing chargers. It is a LM35 temperature sensor connected to a DMM. The LM35 is fairly precise and delivers 0.01 volt for each degree Centigrade, i.e. 0.25 volt is 25°C. The LM35 needs some power, between 6 volt and 35 volt is fine and 60uA in current. A 9 volt battery will last about 1 year.

The LM35 is bought as an accesory for an B6 charger, this means it includes a magnetic holder that fits on a battery. In addition to the sensor I needed a battery box, some wires and some heat shrink.

Heat shrink is placed as far away from the solder points as possible.

Isolation is stripped and wires tinned.

Everything soldered together.

First test. The sensor is 25.4°C

The heat shrink is shrinked, both inner and output tubes.

Final test, box is ready.

Power supply

Now I was upgrading, I decided to also upgrade the power supplies to "precision" power supplies.

This means that my charge voltage will change a bit and the capacity measurements will be slightly different. With this upgrade I hope to make the two test stations equal enough to test any battery on either one.