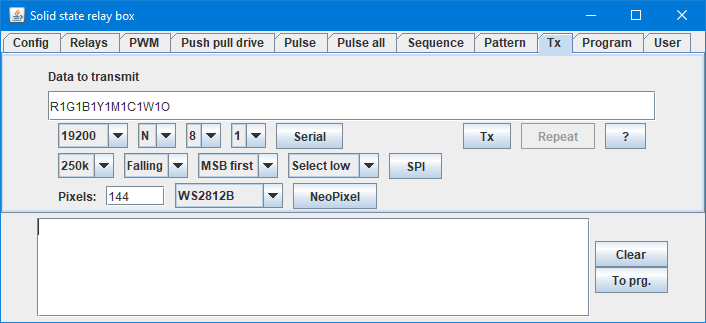

PIXEL 143 GRBW TX w4 SELECTPGM PIXEL 144 GRBW TX w4 PGM1 PIXEL 144 GRBW TX r4 PGM2 PIXEL 144 GRBW TX g4 PGM3 PIXEL 144 GRBW TX b4

PROGRAM PIXEL 143 GRBW|TX w3|SELECTPGM|PIXEL 144 GRBW|TX w4|PGM1 PA PIXEL 144 GRBW|TX r4|PGM2|PIXEL 144 GRBW|TX g4|PGM3|PIXEL 144 GRBW PA TX b4