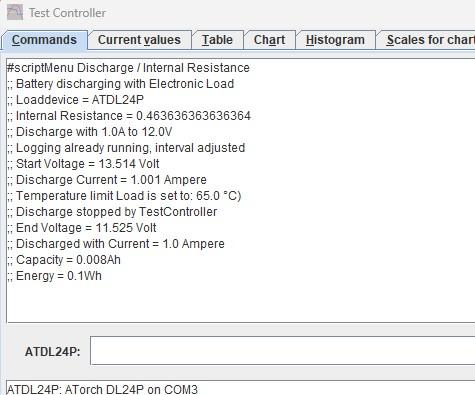

Code:

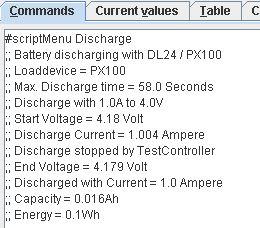

#scriptMenu Discharge

#logcmds 0

="Battery discharging with DL24 / PX100"

=var endVoltage=0

=var testCurrent=1

=var endVoltageLoad = endVoltage-0.05

=var stepTime=1

=var Voltage

=var startCurrent

=var stopByLoad=2

=var addCapacity=1;

=var addEnergy=1;

=var reset=1

=var Timelimit=0

=var timelimit=72000

=var Timecheck=0

=var load=getDevice("Load")

="Loaddevice = " + load

=setOn(load,0);

=setCurrent(load,testCurrent)

; --------------------------------------------------------------

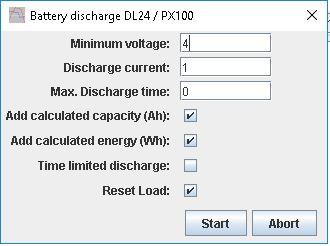

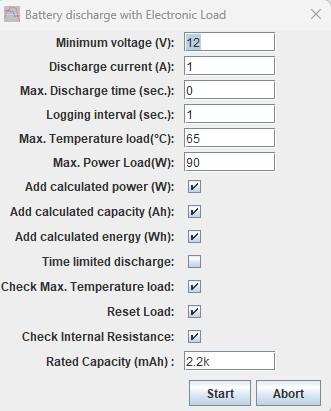

#popupInit "Battery discharge DL24 / PX100"

#popupNumber "Minimum voltage" endVoltage 0.5 60 "The fully discharged voltage for the battery"

#popupNumber "Discharge current" testCurrent 0.1 5 "Current used for discharge"

#popupNumber "Max. Discharge time" Timelimit 0 72000 "Max. Discharge time in Seconds"

#popupCheckbox "Add calculated capacity (Ah)" addCapacity "Add Math.Capacity expression"

#popupCheckbox "Add calculated energy (Wh)" addEnergy "Add Math.Energy expression"

#popupCheckbox "Time limited discharge" Timecheck "Activate Time limit"

#popupCheckbox "Reset Load" reset "Reset Load before start"

#popupButtons Start ok Abort

#popupShow

; --------------------------------------------------------------

#if !ok

="Test aborted"

#return

#endif

#math

#if addCapacity

#math Capacity Ah SumTimeHour 0 (nameCurrent(load))

#endif

#if addEnergy

#math Energy Wh SumTimeHour 0 (nameCurrent(load)+"*"+nameVoltage(load))

#endif

#if Timecheck

=timelimit=Timelimit

="Max. Discharge time = " +Timelimit + " Seconds"

#endif

#if reset

(load):reset

#endif

#delay 1

=endVoltageLoad=(endVoltage-0.05)

#delay 0.5

=setCurrent(load,testCurrent)

#delay 0.5

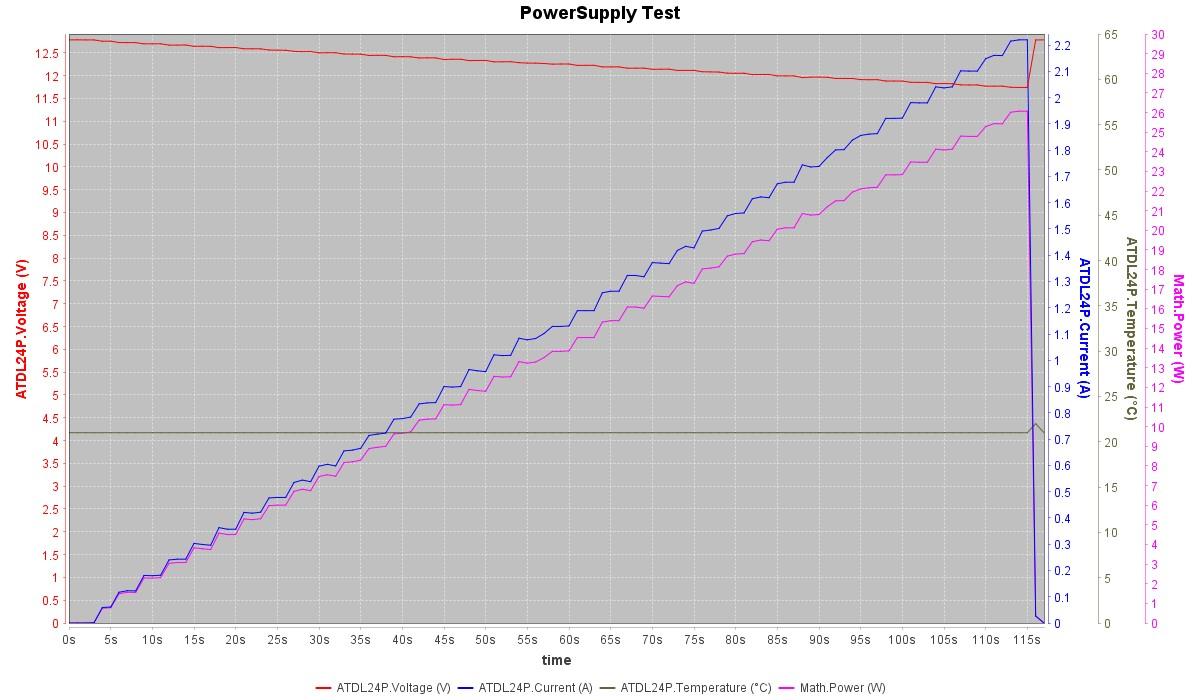

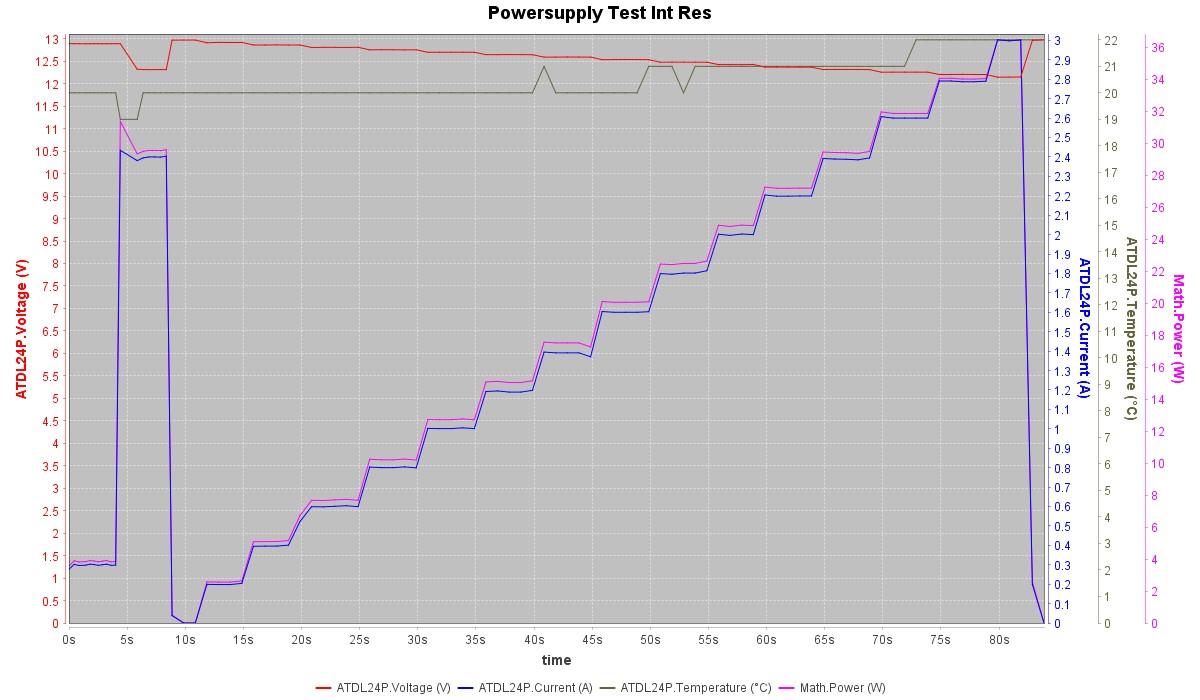

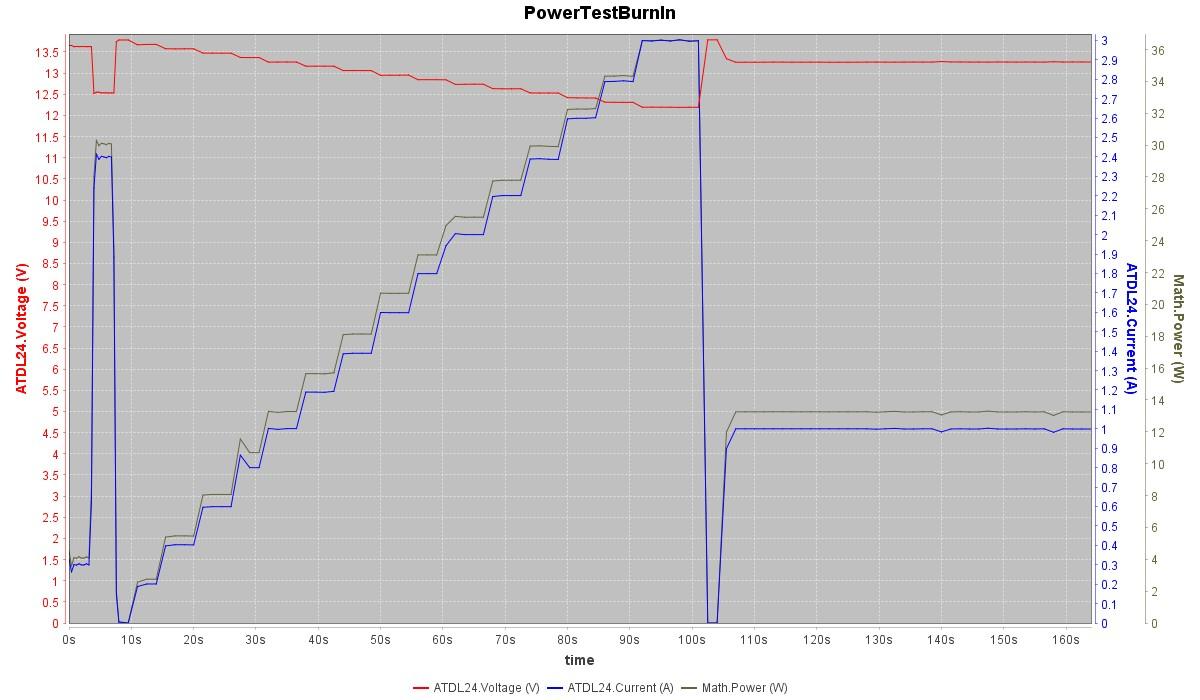

="Discharge with "+testCurrent+"A to "+endVoltage+"V";

=setVoltage(load,endVoltageLoad)

#delay 0.5

=setCurrent(load,testCurrent)

#delay 0.5

#delay 0.5

=setOn(load,1);

#delay 0.5

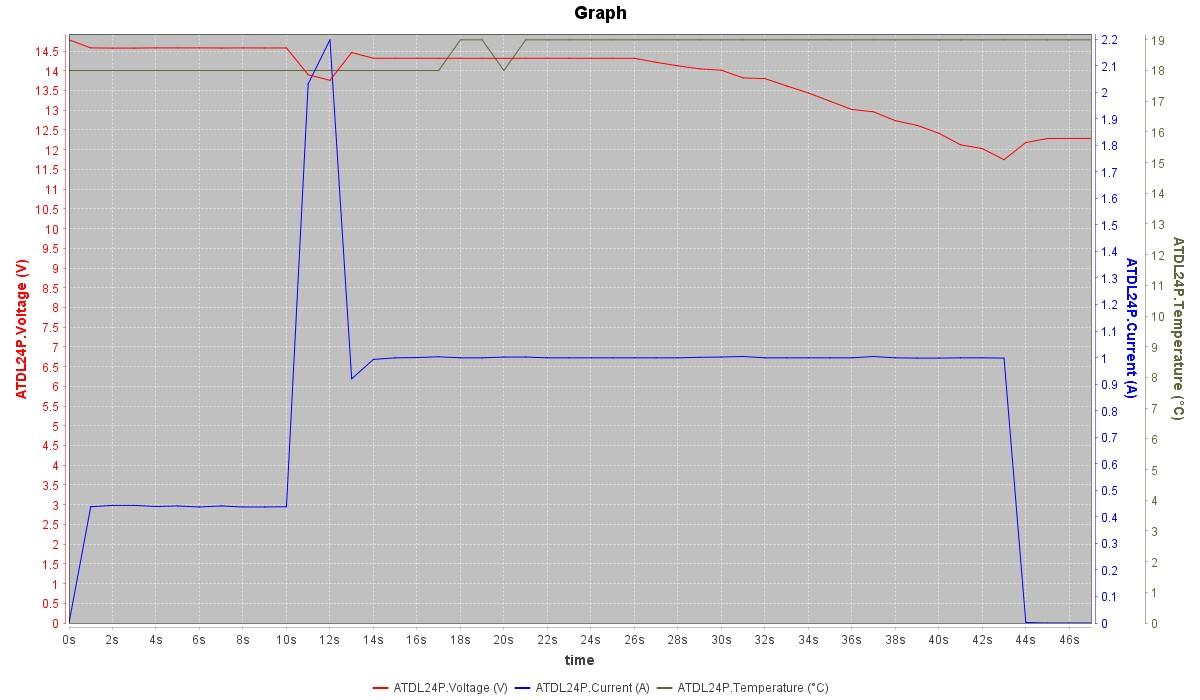

#log (stepTime)

#ChartCurves (load+".Voltage") (load+".Current) (load+".Temperature) RD6012.Voltage RD6012.Current

#haslogged

#haslogged

="Start Voltage = "+tableCalcMax((load+".Voltage"),tableRows()-2)+" Volt"

="Discharge Current = "+tableCalcMax((load+".Current"),tableRows()-2)+" Ampere"

=startCurrent=tableCalcMax((load+".Current"),tableRows()-2)

#haslogged

#haslogged

#haslogged

#haslogged

#if Timecheck then {

#wait (tableCalcMax((load+".Voltage"),tableRows()-6)>endVoltage) and (tableCalcMax((load+".Current"),tableRows()-6)>(0.5*testCurrent)) and timeendVoltage) and (tableCalcMax((load+".Current"),tableRows()-6)>(0.5*testCurrent))

}

#endif

=setOn(load,0);

#log 0

#if (tableCalcMax((load+".Current"),tableRows()-6)<(0.5*testCurrent)) then {

=stopByLoad=1

}

#endif

#log 0

#if startCurrent<0.1 then

="Discharge not started, Input Voltage to low"

#else

#endif

#if stopByLoad<2 then {

="Discharge stopped by Load"

}

#endif

#if stopByLoad>1 then {

="Discharge stopped by TestController"

}

#endif

="End Voltage = "+tableCalcMax((load+".Voltage"),tableRows()-3)+" Volt";

="Discharged with Current = "+testCurrent+" Ampere"

="Capacity = "+(tableCalcMax((load+".Capacity"),tableRows()-2))+"Ah"

="Energy = "+(tableCalcMax((load+".Energy"),tableRows()-2))+"Wh"